| +91 98422 32470 |

Services

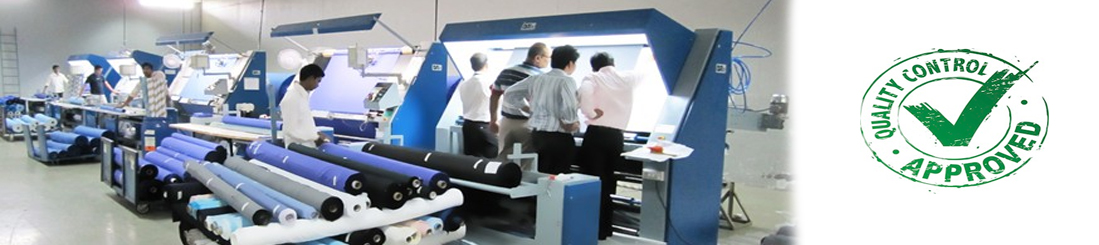

We are counted among leading service providers engaged in offering third party inspection services for quality checks for the factories. Designed and developed using advanced techniques our range of services includes factory audit, Cut parts, Garments 100% audit services, initial production services, in-production check, final random inspection and loading supervision. Our services are highly appreciated by clients for their accuracy, hassle free & timely execution, and cost effective prices.

Textile Inspection Services

We hold expertise in rendering reliable and effective Textile Inspection Services that ensure delivery of products created as per buyer and seller agreement. Employed at production centers, our experts perform subjective evaluation (also termed as attribute characteristics) of the products as per the standards of ISO / ASQC / ANSI / MIL STD. In addition, they incorporate 10 point & 4 point System for Greige/Finished Fabrics of woven/knitted varieties or any other specified standards. Further, the team analyzes the standard specified attributes with product's features including a wise verification or final verification (FRI) procedure. It can be summarized as:

We hold expertise in rendering reliable and effective Textile Inspection Services that ensure delivery of products created as per buyer and seller agreement. Employed at production centers, our experts perform subjective evaluation (also termed as attribute characteristics) of the products as per the standards of ISO / ASQC / ANSI / MIL STD. In addition, they incorporate 10 point & 4 point System for Greige/Finished Fabrics of woven/knitted varieties or any other specified standards. Further, the team analyzes the standard specified attributes with product's features including a wise verification or final verification (FRI) procedure. It can be summarized as:

Textile Testing Service

Leveraging on our rich industry experience and expertise, we have been able to render hassle free Textile Testing service to valued clients. Empowered with all requisite tools and technology, our professionals leave no stone unturned in offering assistance for various tests like color fastness to washing (home laundry), perspiration, water, dry cleaning, rubbing / crocking, and appearance retention after home laundering and dry cleaning. Our ultra modern laboratory division also supports us in undertaking dimensional stability for washing & dry cleaning, construction parameters (like EPI / PPI, CPI / WPI, Count, GSM), care label recommendation and PH and basic analytical tests.

Leveraging on our rich industry experience and expertise, we have been able to render hassle free Textile Testing service to valued clients. Empowered with all requisite tools and technology, our professionals leave no stone unturned in offering assistance for various tests like color fastness to washing (home laundry), perspiration, water, dry cleaning, rubbing / crocking, and appearance retention after home laundering and dry cleaning. Our ultra modern laboratory division also supports us in undertaking dimensional stability for washing & dry cleaning, construction parameters (like EPI / PPI, CPI / WPI, Count, GSM), care label recommendation and PH and basic analytical tests.

Auditing Services

V & A Textile Inspection and Testing Services has the vision to lead the way in developing innovative approaches while introducing new practices and standards. Our client-focused auditing services for Textile, Apparel and Footwear range from verifying individual transactions to full process inspection, development, safety and compliance checks. Assessing the quality of a facility, its procedures and systems is an important job best done by trained auditors. We can audit manufacturing facilities around the world, providing an independent assessment of the factory’s quality systems and an independent view of the facility’s capability of producing consistent quality footwear.

V & A Textile Inspection and Testing Services has the vision to lead the way in developing innovative approaches while introducing new practices and standards. Our client-focused auditing services for Textile, Apparel and Footwear range from verifying individual transactions to full process inspection, development, safety and compliance checks. Assessing the quality of a facility, its procedures and systems is an important job best done by trained auditors. We can audit manufacturing facilities around the world, providing an independent assessment of the factory’s quality systems and an independent view of the facility’s capability of producing consistent quality footwear.

Garment Consultant

Our domain expertise enables us in rendering reliable and accurateConsultancy Services. We have employed a team of expert professionals that offers our services after gaining the in-depth knowledge about the requirements of the clients. Their expertise and efficiency supports us in rendering highly effective services in the arena of following:

Our domain expertise enables us in rendering reliable and accurateConsultancy Services. We have employed a team of expert professionals that offers our services after gaining the in-depth knowledge about the requirements of the clients. Their expertise and efficiency supports us in rendering highly effective services in the arena of following:

Third Party Inspection Services

Our organization is engaged in offering high end Third Party-Inspections services that help in improving the product quality, with a reduction in client complaints, non-compliance and product recalls. Supported by a team of expert professionals, these inspection procedures are designed and developed to offer hassle free experience to clients. Offered at most competitive prices, our inspection services include:

Our organization is engaged in offering high end Third Party-Inspections services that help in improving the product quality, with a reduction in client complaints, non-compliance and product recalls. Supported by a team of expert professionals, these inspection procedures are designed and developed to offer hassle free experience to clients. Offered at most competitive prices, our inspection services include:

Fabric Inspection

Fabric Inspection is systematic observation of fabrics to decide whether it meets: Client’s specification in terms of count/construction, color, design, measurement specifications, hand/feel and other specific quality parameters laid down by the clients. We are one of the leading Fabric Sourcing Concern, we source all kind of fabrics. like knits, woven n silk fabrics.

Fabric Inspection is systematic observation of fabrics to decide whether it meets: Client’s specification in terms of count/construction, color, design, measurement specifications, hand/feel and other specific quality parameters laid down by the clients. We are one of the leading Fabric Sourcing Concern, we source all kind of fabrics. like knits, woven n silk fabrics.

Total Quality Solutions

We hold expertise in rendering reliable and effective Textile Inspection Services that ensure delivery of products created as per buyer and seller agreement. Employed at production centers, our experts perform subjective evaluation (also termed as attribute characteristics) of the products as per the standards of ISO / ASQC / ANSI / MIL STD. In addition, they incorporate 10 point & 4 point System for Greige/Finished Fabrics of woven/knitted varieties or any other specified standards. Further, the team analyzes the standard specified attributes with product's features including a wise verification or final verification (FRI) procedure. It can be summarized as:

We hold expertise in rendering reliable and effective Textile Inspection Services that ensure delivery of products created as per buyer and seller agreement. Employed at production centers, our experts perform subjective evaluation (also termed as attribute characteristics) of the products as per the standards of ISO / ASQC / ANSI / MIL STD. In addition, they incorporate 10 point & 4 point System for Greige/Finished Fabrics of woven/knitted varieties or any other specified standards. Further, the team analyzes the standard specified attributes with product's features including a wise verification or final verification (FRI) procedure. It can be summarized as:

Quick Contact

Mr.Jaya Krishna.N

+91 98422 32470

Buyer's Handled

Enquiry

Contact Us

|

112H Asher Nagar, Behind Indian Oil Bunk, Avinashi Road,SAP, Tirupur - 641 603. | |

|

info@vandatextileinspection.com | |

|

+91 98422 32470, +91 99944 60649 |